What is Maximum Run Length?

What does Maximum Run Length mean, why is it listed on Strips Lights and why does it change?

Maximum run length means the maximum amount of distance that a strip light can be laid out with a single connection to a power supply or controller. For example, our W-Series Ultra Bright Strip Light has a maximum run length of 16.4 Feet. This means that if you wanted to make a strip light run off 25 feet you would need to have the strip powered by more than one set of leads. In the case of the 25 foot example, there would be a lead going to the power supply for the first 16.4 feet and then a second independent lead going back to power the remaining 8.6 feet.

Why is there this limitation?

The limitation actually comes from Ohms Law! The relationship of the concepts of Electricity are Voltage = Current times Resistance

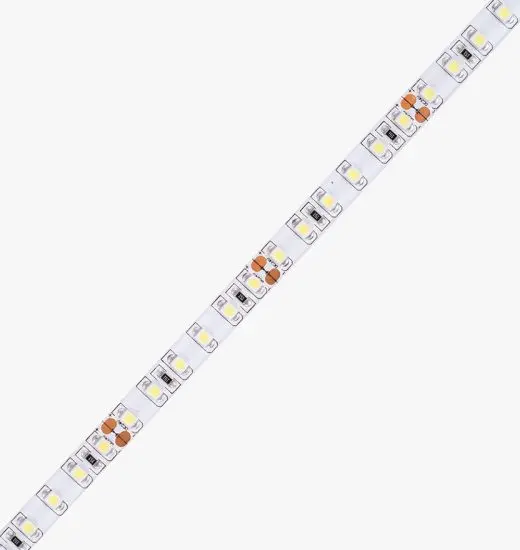

This relates to strips lights because of how a strip light is constructed. A strip light contains many components but the ones we are concerned with for voltage drop are:

- LEDs which have specific voltage and current requirements to illuminate correctly. For strip lights, the voltage should remain constant and the power supplies used for LED Strip Lights are Constant Voltage power supplies. Our Strip Lights are available in both 12 Volt and 24 Volt versions.

View Our LED Strip Lights - Flexible Circuit Board which is the tape that the LEDs sit on. It is composed of wires traces and insulating board. In general , wires have different "gauges" The gauge of a wire is determined by the area of a cross section of a wire. The capacity of the wire to allow electricity is determined by this area.

- A larger wire diameter allows more power to flow and conversely a smaller wire allows less power to flow. This is the basics of resistance. The resistance of electricity to flow through the wire.

It is the demands of the LEDS for voltage and current in relation to the size and resistance that limits the amount of capacity the wires in the Flexible Circuit Board. A longer strip has more LEDS and longer wires and uses more power. The maximum run length is a distance that has minimum effect on the ratio. Exceeding the posted maximum run length in the specs means that the relationship of Voltage to Current and Resistance will cause several things to happen:

- The resistance will be higher. More resistance means more restriction on the ability of the LEDS to receive the power they need. The Power Supply will attempt to maintain the constant voltage needed by supplying more power. This is in the form of Current.

- The Power Supply has protection built in that limits the maximum amount of current flow. Often times when an installation has a power supply stop powering it is because the maximum current was exceeded. Sizing a Power Supply to be larger is one solution, but that only makes the other effect of running beyond the maximum run length an issue. Higher current and resistance cause a wire to get warmer. LEDs do NOT like heat and this will ultimately reduce the life of your strip lights.

- The reason some strip lights are able to run different maximum run lengths is again because of Ohms Law. Lower brightness LEDs like our N-Series Standard Bright use less power. Because of the lower power requirements the 24 Volt version of this strip has a longer maximum run length of 32 feet.

- Another example is that sometimes people will say that they are replacing that old fashioned rope lighting with LED strips and why can't they just run it the same length as before. The strip lights are substantially brighter and therefore use a lot more power! Ohms Law is again the reason!

So if the limitation is the size of the wire why don't manufactures just make the wires larger?

The determination of the size of the internal wires is a compromise balancing strip flexibility and cost of materials to achieve a product that will accomplish the lighting needs for the majority of applications at an affordable cost.